Surfacing of Silage Clamps using a specialist Breedon product (Breedon Agricultural HRA)

BREEDON AGRICULTURAL HRA IS MODIFIED HOT ROLLED ASPHALT UTILISING HARD STONE AGGREGATE WITH ELEVATED BINDER CONTENTS, OFFERING EXCELLENT IMPERMEABILITY, AND THUS IMPROVED DURABILITY.

This material has been designed to significantly improve resistance to acidic silage fermentation effluents, urine and dung, whilst also providing a surface which is less abrasive to animal feet when compared to other construction materials.

Applications

- Silage clamps

- Silo floors

- Anaerobic digesters

- Animal house floors (e.g. cow cubicle beds)

- Areas exposed to acidic liquids and effluents

Technical Data

BREEDON Agricultural HRA has been found to outperform HRA 35/14 F surf 40/60 Granite (often used for silage clamps) in the following respects:

- Reduced in situ air voids (after 50 blows to both sides in a Marshall Hammer).

- Lower mass loss after 48 hours immersion in lactic acid.

- Higher retained stability after 2, 7 and 28 days immersion in acetic acid.

Construction

Layer depths are dependant on sub-grade quality and anticipated loadings. Typical construction thicknesses for new builds are 150 – 250mm of sub-base, 80mm of bituminous binder course, and 40 – 50mm of BREEDON Agricultural HRA.

Drainage should always be taken into consideration. Limestone should not be used in any construction materials to prevent acid attack.

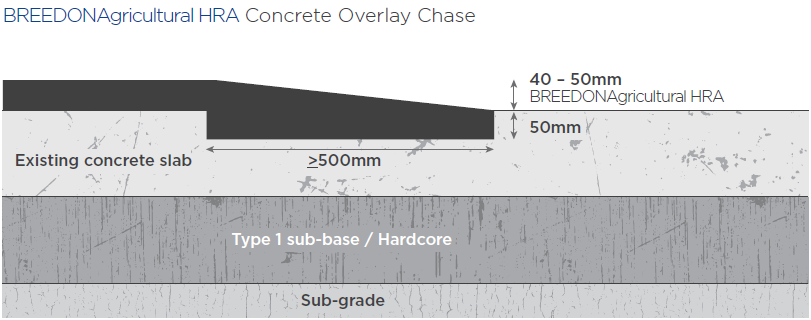

If overlaying concrete, this should be high pressure washed and cut back to remove all loose and deleterious material. Joints, cracks and potholes cleaned, filled and repaired appropriately. To avoid creating a thin edge, a chase of at least 50mm deep by 500mm wide should be cut at the front of floors or clamps to give a smooth level change (see diagram).

A suitable cationic tack or bond coat should be applied evenly to the concrete and allowed to ‘break’ (i.e. turn from brown to black). The HRA can then be laid and compacted. Sealants or waterbars should be used to caulk joints, walls and stanchions.

Joints and cracks in concrete will eventually result in reflective cracking in asphalt overlays. Using BREEDON Flex SAMI and/or a suitable grid system beneath the HRA will significantly delay the onset of this occurring.

Benefits

- Reduced whole life costing (WLC). Smooth, homogenous surface.

- Does not require the application of pre-coated chippings.

- Usable within 24 hours of installation. Excellent resistance to acid, dung, urine and abrasion from hooves when compared with ‘standard’ recipe and design HRAs.

- Reduced usage of bedding material and increased animal comfort as a result of good insulation in animal houses.

- Easily maintained, enabling good hygiene practices.

- Cleaner conditions reduce livestock disease, with less deterioration and therefore maintenance.

- Can be laid continuously, reducing the need for joints.

- Expansion joints are unnecessary, lowering maintenance to avoid decline.

- Non-frost-susceptible.

- Excellent impermeability characteristics when compared with ‘standard’ bituminous materials.

- Cost benefits when compared to other construction materials.

Maintenance & Repair

- The material should not be used for permanent parking, or for pallet/feed trough storage areas.

- Oils and dung should be removed as soon as practicable.

- Damages to the surface should be repaired with suitable impermeable bituminous products.

- Floor and wall joints should be inspected at least annually and be appropriately repaired if found to be defective.

Why Choose Breedon Proprietary Materials?

The Proprietary Materials offered by Breedon are extensively designed and rigorously tested to exceed the performances of traditionally used bituminous materials in specific applications. Our Proprietary Materials often include specialised additives to achieve high levels of operation.

Precautions and Limitations

Asphalt remains relatively soft for up to one year after laying; until it has time to oxidise and harden (i.e. elasticity is reduced). It is recommended that the surface is not trafficked for at least 24 hours following installation, when it is most susceptible to damage.

When trafficked by vehicles, it is recommended that they are moving when the wheels are turned. If a vehicle is stationary when tyres are turned (particularly with modern power steering), the asphalt can be displaced and marked by stresses applied at that particular point.

It is also recommended that (wherever possible) vehicles are parked in different positions to avoid marking the asphalt, and heavy vehicles, trailers, plant, machinery and ladders with small footprints are parked on wooden boards to disperse the loading. Fuel spillages should also be contained and cleaned up as soon as possible as these will compromise durability.

Recommended procedure for removing diesel spillages is as follows:

- Stem the leak.

- If necessary, contain the spillage by deploying booms around the source and block any drains.

- Apply absorbent granules (e.g cat litter) or sand to the spillage area.

- Sweep up the absorbent granules and dispose of in accordance with environmental regulations.

- Scrub the surface using a mild detergent. Any effluent resulting from the clean-up activity must not be washed into surface water drains as it is an offence under the Water Resources Act 1991.

Availability

BREEDON Agricultural HRA installation can be completed all year round (depending on climatic conditions), by JC Surfacing.